869

Views & Citations10

Likes & Shares

Marginal fit of the crown is a key assessment of the

fixed partial denture quality. Numerous studies have been performed to evaluate

the marginal fit of CAD/CAM all-ceramic crowns fabricated under ideal

conditions, but very few studies have investigated the impact of real clinical

factors, such as the quality of the abutment preparation. The purpose of this

study is to evaluate the effect of preparation quality on the marginal fit of

CAD/CAM crowns. Fifteen dental clinicians made three preparations of the upper

left first molar on the typodont, and the quality of the preparation was

objectively determined using preparation analyzer software. CAD/CAM crowns were

fabricated using the standard digital workflow on the CEREC System. The

marginal fit of the crown was measured using the Triple-Scan Protocol, and

digitally analyzed and measured in 3D with computer software. Out of 45

prepared abutments, 19 were rated “poor” (PP) and 26 were rated “good” (GP).

The average marginal gap in PP and GP were 82.13 (±9.41) µm and 62.12 (±10.11)

µm, respectively. Statistical analysis with two-tailed t-test showed p-value

< 0.01, indicating significant difference between the two groups. Within the

limitations of this study, the quality of the margin preparation has

significant effect on the marginal fitness of the CAD/CAM all-ceramic crown

Keywords:

Preparation quality, CAD/CAM, Triple scan protocol, Over-mill, Marginal

fitness

Abbreviations:

GP: Good Preparation; PP: Poor Preparation; ME: Marginal Edge; MR: Marginal

Ramp; TSP: Triple Scan Protocol

INTRODUCTION

Recent developments in dental CAD/CAM have vastly improved its

technical maturity, producing restorations that are not only clinically

acceptable and reliable, but cost-effective as well [1]. An abundance of

literature exists that compare the quality and accuracy of restorations

fabricated from conventional workflow versus those from digital procedures. In

general, their conclusions can be split into two groups. Either the studies

concluded that there was no significant difference in quality [2-4], or that

digital workflows are more accurate [5-7].

Fitness of a restoration is a measure of accuracy, and it can be

evaluated by measuring the space between the restoration and the underlying

abutment. McLean et al conducted a 5-year clinical study evaluating marginal

fit of crowns, and determined that marginal gaps up to 120 µm were acceptable

[8]. Several authors also considered marginal gaps between 100 and 150 µm to be

clinically acceptable [9-11]. The source of this large variance in accuracy is

of considerable clinical interest, considering that the resolution of most

dental milling machines is around 25 µm. In an in-vitro study, the authors

compared the marginal gaps of lithium disilicate crowns fabricated by using

three different impressions techniques: one conventional and two digital. The

typodont tooth was prepared extra-orally with a clear guide, and the marginal

gaps of the final crowns were measured using a stereomicroscope. The overall

marginal gaps for conventional and two digital methods were 112.3 µm, 89.8 µm,

and 89.6 µm, respectively [3]. In another study extracted molars were prepared

extra-orally to the recommended reduction guidelines, and the marginal fitness

of their respective CAD/CAM crowns were compared. The study also concluded that

marginal discrepancies in all cases met the clinically-acceptable standard

[12,13]. Similar conclusions can be observed from other similar studies that

compared marginal fitness of CAD/CAM crowns [14,15].

Most of these studies use ideal abutments either prepared extra-orally

or replicated using metal casts. In real clinical situations, ideal

preparations are impractical due to a multitude of environmental, human, and

technical factors. One study that attempted to investigate the human factor

examined the marginal fit of crowns fabricated with the E4Dsystem (PLANMECA,

Finland) and its correlation to the quality of the abutment preparation [16].

The prepared abutments were categorized into “excellent”, “fair”, or “poor”

quality based on visual inspection. In its discussion, the authors admitted to

the possibility of bias and subjectivity with this method. Therefore, the

purpose of this study is to use an objective assessment of preparation quality,

and to investigate whether the preparation quality has a significant effect on

the fitness of the final CAD/CAM crown.

METHOD

Preparation

Fifteen dentists from a teaching hospital, with clinical experiences

ranging from 2 to 18 years, were recruited as subjects of this study. All

participants were given a mandatory 10-minute presentation that reviewed

important preparation parameters. Each participant prepared the same tooth

(#26) on the typodont (Kao Dental GmbH, Germany) three times. The first

preparation was preceded by a 5-minute calibration period, during which the

subjects were able to familiarize themselves with the hardware. All subjects

were provided with identical sets of new burs (Figure 1). In the period between each preparation, the prepared

abutment tooth was removed from the phantom-head and the typodont. The subjects

were not allowed to see the removed teeth until all three preparations were

finished. Once the preparation phase has completed for the subject, the three

abutment teeth were collected, rinsed with tap water, labeled, and stored in

separate containers.

Crown Fabrication

The CEREC Omnicam (Dentsply-Sirona, Germany) was used to create the

digital impression of the prepared abutments. Once the scan data has been

acquired, it was analyzed using the Preparation Analyzer tool to assess the

margin quality of the preparation, which was subsequently categorized into two

groups. If the Preparation Analysis showed no warning, then the preparation is

assigned into the “good preparation” (GP) group. If the software showed one or

more warnings on the margin, then the preparation is designated as “poor

preparation” (PG).

For digital restoration design, the original morphology of the

unprepared tooth was used was used an index. The material selected for

fabrication is the feldspathic porcelain Mark II 14-mm bloc (VITA, Germany),

and all restoration parameters were set to manufacturer’s recommended defaults.

The restorations were milled in the In Lab MCXL (Dentsply-Sirona, Germany)

using extra-fine settings with 12Sburs. The burs were replaced after having

milled 10 crowns. Each crown was visually inspected for milling defects and

re-milled in the off-chance that defects were detected. Then the sprues were

removed and polished via a low-speed hand-piece, and the lumen surfaces

steam-cleaned before trying-in on the abutment.

Analysis

The primary technique used for the data acquisition in 3D marginal fit

analysis is the Triple Scan Protocol (TSP) [17]. In this study, the TRIOS

intra-oral scanner (3Shape, Denmark) was used as the scanner in the protocol.

The Triple-Scan Protocol consists of three scans. First, the crown is fixed in

place with beading wax, with the lumen surface facing up and all external axial

surfaces exposed (Scan #1). The TRIOS was then used to scan using

high-resolution mode. The number of 3D image stacks was limited to under 300,

irrespective of the scanning time. After scanning was completed and inspected

in the software for holes, the file was converted and saved into ASCII STL file

format. For the second scan of the protocol, the prepared abutment scanned in a

similar method to the previous step, and the final model was converted into STL

file format (Scan#2). Finally, the third scan of TSP consists of both the crown

and the abutment in their seated positions (Figure 1). Before the scan, the

porcelain crowns were seated onto the abutments with light-body silicone (3M).

Maximum finger pressure was applied for 5 minutes until setting, and entire

specimen was scanned using the same method as the previous steps (Scan #3).

3D Marginal Analysis

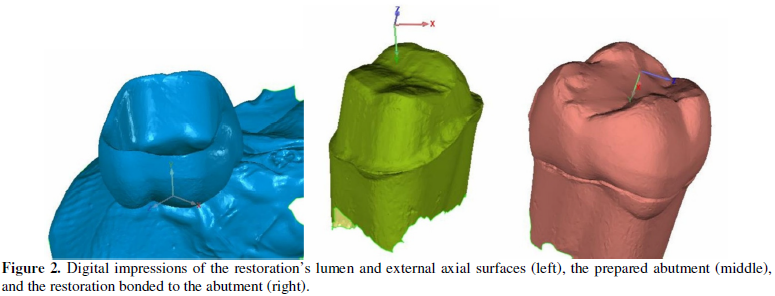

Geomagic Studio was used for to create 3D registration of the crown

(Scan #1) and the abutment scan data (Scan #2), using the scan data (Scan #3)

as reference. The margin of the prepared abutment was divided into two regions.

The area from the edge of the margin to the highest curvature before the axial

wall was designated as the marginal ramp (MR) (Figure 2). The outer band of MR consisting of all mesh triangles in

contact with the edge boundary was designated as the marginal edge (ME). Once

these two regions were specified on the abutment, their average distance to the

lumen side of the corresponding crown model can be determined using standard

software functions. For each region, the mean and maximum distances across all

sampling points were calculated.

RESULTS

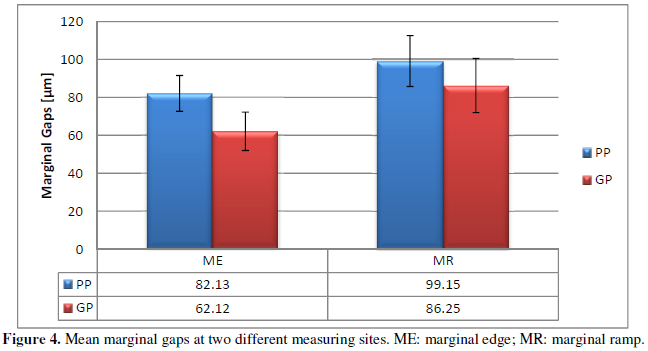

The numbers of samples in PP and PG groups were 19 and 26,

respectively. The mean gap measurements using data acquired from TSP were as

followed; For ME, the mean gap size for PP was 82.13 µm (±9.41), while the mean

gap size for GP was 62.12 µm (±10.11). For MR, the mean gap size for PP was

99.15 µm(±13.46), while the mean gap size for GP was 86.25 µm (±14.23) (Figure 3). No samples were rejected

during inspection.

STATISTICAL ANALYSIS

The results for data from ME and MR indicated statistical significance

(p < 0.01) between PP and GP values. For ME results, the t-score was 6.82

with 43 degrees of freedom. For MR results, the t-score was 2.87 with 43

degrees of freedom.

DISCUSSION

For CAD/CAM restorations, marginal fitness is often of primary concern

because it directly correlates to the long-term health of the dentition and the

surrounding tissue [13,18,19]. Marginal fitness, or discrepancy, is defined as the

“vertical dimension from the finish line of the preparation to the margin of

the restoration” [20]. Poor marginal adaptation of the restoration can increase

micro leakage and plaque accumulation, leading to cement dissolution, secondary

caries, and periodontal disease [21]. There is, however, no clear guideline for

clinically acceptable marginal fit. Christensen [22] considered 39 µm to be the

acceptable marginal discrepancy according to the linear regression prediction

formula. Several authors also considered marginal discrepancies between 100 and

150 µm to be clinically acceptable [8-11].

While digital workflows have shown to produce clinically acceptable

margins [3,12,13], these kinds of studies mostly utilize abutments that were

optimally prepared in-vitro. Ucar et al. [23] used machined steel dies to

evaluate the internal fitness of laser-sintered crowns. Seker et al. [1] and

Baig et al. [15] prepared extracted premolars with a uniform 1 mm rounded

shoulder margin to evaluate marginal fit of CAD/CAM restorations. These studies

failed to capture the inevitable variance caused by human error. In a real

clinical setting, factors such as poor viewing angles, inadequate lighting,

mouth opening limitations, and the skills of the dentist can potentially cause

teeth preparations to become suboptimal. Therefore, the results from these

previous studies represent the best-case scenarios that are very unlikely to

occur.

Since in practice, dentists are able to detect gaps at only the margins

with a dental probe [22], the criteria for preparation quality in this study is

limited to the marginal area. In this study, the average gaps at ME for the PP

and PG groups were 82.13 µm and 62.12 µm, respectively. The ME marks the band

of area directly adjacent to the edge of the finish line, and the gap values in

this study were all within the clinically acceptable value of 120 µm [8].

Furthermore, they are also in agreement with other similar studies that used

intra-oral scanners to fabricate single crown restorations [13,15,24-26].

According to a systemic review [27], which performed a meta-analysis on the

evaluation of marginal fit of single-unit full coverage ceramic restorations,

the mean value of the marginal fit for in-vitro restorations fabricated after

digital impressions was 63.3 µm(95% CI: 50.5–76.0 µm). Considering that these

studies used optimally prepared abutments under controlled settings, the

marginal fitness obtained for the GP group in this study (62.12 µm) is very

close to the value obtained in the systemic review. This seems to suggest that

if the marginal preparation is of sufficiently quality, then near-optimal

marginal fitness can be achieved. On the other hand, if there are areas of

roughness or acute angles that can be detected by the analysis software, then

these imperfections are transferred to the fitness of the final crown.

The software used for preparation quality assessment, Preparation

Analysis, is a simplified version of prep Check (Dentsply-Sirona). It checks

the curvature process of the preparation margin, and if the margin exceeds a

determined section length of a predefined curvature, the region is highlighted

as a warning. The predefined curvature can be indentations or protrusions, and

it is correlated to the milling process. The marginal fit of the CAD/CAM crown

is dependent on how accurately the milling device can reproduce the contours of

the preparation. Since milling is performed with burs, the radius of the bur

poses a physical limitation on how fine a detail can be milled. Therefore, small

features or contours smaller (i.e. rough surfaces, sharp angles) cannot be

perfectly reproduced. When this problem is encountered during the milling

pathway analysis, there are two options for the software algorithm. First, to

ensure complete seating of the crown, the software will generate a milling path

that guarantees milling of all surface features.

This is called over-milling [28], and it necessitates the creation of

extra cement space around the problem region as a compromise. The alternative

method is to simply ignore the geometries that cannot be milled, and instead

favor the preservation of crown integrity. This is called under-milling, and it

can potentially cause an inability for the crown to completely seat. For the

marginal regions with severe enough roughness, either milling strategy will

result in increased marginal gaps.

In a study, researchers fabricated 75 crowns based on abutments of

varied preparation quality determined by visual inspection [16]. The study

concluded that preparation quality has a significant effect on marginal gap

when using chair side CAD/CAM systems and that common error in preparation

design had a negative impact on the mean marginal gap. While our results

concur, the determination of quality by visual inspection was subject to

potential bias. In fact, several other studies have evaluated the intra-rater

variability for the assessment of dental preparation quality, and found the

intra-rater agreement to be between 0.53 and 0.68 [29,30], representing up to

22% variance in binary pass/fail decisions [31]. In contrast, our study uses

the built-in preparation analysis tool (Dentsply-Sirona, Germany) to

objectively evaluate the quality of the preparation.

The methods of evaluating the crown fitness have been well established

in literature. For marginal fit, studies have used the optical microscope

[1,13,15,32-35], scanning electron microscope [1,33,34] or silicone replica

[4,13,14], [16,21,25,32,36]. According a systemic review by Nawafleh et al.

[37], the direct-viewing technique (i.e. microscopes) is the most common method

of studying marginal fitness, accounting for 47.5% of the 183 papers reviewed

in the study. The study concluded that the there was a substantial lack of

consensus relating to marginal adaptation of various crowns, because of the

large variance 0in the results obtained. The silicone replica method, or any

embed-then-section methods [24], for measuring marginal and internal fitness

suffers from one major flaw: using a 2D method to analyze 3D metrics. A recent

study by Kuhn et al. [38] compares analog and digital quantitative and

qualitative analysis for the fit of dental copings, and concluded that the

analog 2D replica technique revealed a loss of information due to the cutting

process. In order to maximize the retention of data, our study employed TSP and

digital software analysis for true 3D measurement.

Recently the Triple-Scan Protocol (TSP) was described and validated for

the fitting accuracy assessment of cast metallic frameworks, titanium copings, and

lithium disilicate partial crowns [17]. This protocol allows for the virtual

registration of two scanned models (abutment and crown) in relation to the

third reference model (crown bonded to abutment). The TSP is non-destructive

and eliminates a great number of shortcomings of 2D fitting accuracy assessment

techniques that have been applied routinely in other studies.

In a study by Boitelle that used the TSP methodology to evaluate 3D

fitting accuracy of CAD/CAM copings, the marginal and internal fitness of the

restoration was divided into three regions [39]. Using the height of the

abutment as the reference, the abutment was separated into the marginal (bottom

15%), the occlusal (top 15%), and the axial (middle 70%) zones. While this

strategy provided a quick method to differentiate various aspects of the

abutment, it would only be useful if the prepared abutment was both axially and

radially symmetrical. Since the teeth were prepared by real clinicians in our

study, the height and width of the margin were highly variable. Therefore, our

study used the morphology of the abutment to delineate different regions. The

mean gap sizes of the marginal area in Boitelle’s study ranged between 54.32 –

66.56 µm, depending on the digital system used, while in our study the

corresponding fitness of the marginal ramp was 86.02 µm.

While the data seems to suggest that even poor-quality preparations can

produce, on average, clinically viable results, these results are only average

values. The presence of variance means that a percentage the margins can

potentially be larger than the acceptable value. The inability for milling

machines to compromise means that there is higher sensitivity to preparation

errors.

CONCLUSIONS

Within the limitations of this study, the following conclusions can be

made:

- There is a significant

difference in the marginal fitness of crowns fabricated from good quality

preparations when compared with those fabricated from poor quality

preparations. Therefore, the null hypothesis is rejected.

- Regardless of preparation quality, the marginal gaps of CAD/CAM crowns were all within the clinically acceptable range.

1.

Şeker E, Ozcelik TB, Rathi N, Yilmaz B (2016) Evaluation of

marginal fit of CAD/CAM restorations fabricated through cone beam

computerized tomography and laboratory scanner data. J Prosthet Dent 115: 47-51.

2.

Berrendero S, Salido MP, Valverde A, Ferreiroa A, Pradíes G

(2016) Influence of conventional and digital intraoral impressions on the fit

of CAD/CAM-fabricated all-ceramic crowns. Clin Oral Investig 20: 2403-2410.

3.

Abdel-Azim T, Rogers K, Elathamna E, Zandinejad A, Metz M, et

al. (2015) Comparison of the marginal fit of lithium disilicate crowns

fabricated with CAD/CAM technology by using conventional impressions and two

intraoral digital scanners. J Prosthet

Dent 114: 554-559.

4.

Ahrberg D, Lauer HC, Ahrberg M, Weigl P (2016) Evaluation of

fit and efficiency of CAD/CAM fabricated all-ceramic restorations based on

direct and indirect digitalization: a double-blinded, randomized clinical

trial. Clin Oral Investig 20:

291-300.

5.

Shembesh M, Ali A, Finkelman M, Weber HP, Zandparsa R (2017) An

In Vitro Comparison of the Marginal Adaptation Accuracy of CAD/CAM Restorations

Using Different Impression Systems: CAD/CAM Marginal Adaptation Accuracy. J Prosthodont 26: 581-586.

6.

Su TS, Sun J (2016) Comparison of marginal and internal fit

of 3-unit ceramic fixed dental prostheses made with either a conventional or

digital impression. J Prosthet Dent 116:

362-367.

7.

Kocaağaoğlu H, Kılınç HI, Albayrak H (2017) Effect of digital

impressions and production protocols on the adaptation of zirconia copings. J Prosthet Dent 117: 102-108.

8.

McLean JW, Von F (1971) The estimation of cement film thickness

by an in vivo technique. Br Dent J 131:

107-111.

9.

Boening KW, Walter MH, Reppel PD (1992) Non-cast titanium

restorations in fixed prosthodontics. J

Oral Rehabil 19: 281-287.

10.

Tsukada G, Tanaka T, Kajihara T, Torii M, Inoue K (2006) Film

thickness and fluidity of various luting cements determined using a trial

indentation meter. Dent Mater 22:

183-188.

11.

Quintas AF, Oliveira F, Bottino MA (2004) Vertical marginal

discrepancy of ceramic copings with different ceramic materials, finish lines,

and luting agents: an in vitro evaluation. J Prosthet Dent 92: 250-257.

12.

Yang X, Lv P, Liu Y, Si W, Feng H (2015) Accuracy of digital

impressions and fitness of single crowns based on digital impressions. Materials 8: 3945-3957.

13.

Ng J, Ruse D, Wyatt C (2014) A comparison of the marginal fit

of crowns fabricated with digital and conventional methods. J Prosthet Dent 112: 555-560.

14.

Colpani JT, Borba M, Della Bona A (2013) Evaluation of

marginal and internal fit of ceramic crown copings. Dent Mater 29: 174-180.

15.

Baig MR, Tan KBC, Nicholls JI (2010) Evaluation of the

marginal fit of a zirconia ceramic computer-aided machined (CAM) crown system. J Prosthet Dent 104: 216-227.

16.

Renne W, McGill ST, Forshee KV, DeFee MR, Mennito AS (2012) Predicting

marginal fit of CAD/CAM crowns based on the presence or absence of common

preparation errors. J Prosthet Dent 108:

310-315.

17.

Holst S, Karl M, Wichmann M, Matta RET (2011) A new

triple-scan protocol for 3D fit assessment of dental restorations. Quintessence Int Berl Ger 42: 651-657.

18.

Reich S, Uhlen S, Gozdowski S, Lohbauer U (2011) Measurement

of cement thickness under lithium disilicate crowns using an impression

material technique. Clin Oral Investig

15: 521-526.

19.

Podhorsky A, Rehmann P, Wöstmann B (2015) Tooth preparation

for full-coverage restorations—a literature review. Clin Oral Investig 19: 959-968.

20.

Kokubo Y, Ohkubo C, Tsumita M, Miyashita A, Vult Von Steyern

P, et al. (2005) Clinical marginal and internal gaps of Procera AllCeram

crowns. J Oral Rehabil 32:

526-530.

21.

Huang Z, Zhang L, Zhu J, Zhao Y, Zhang X (2015) Clinical

Marginal and Internal Fit of Crowns Fabricated Using Different CAD/CAM

Technologies. J Prosthodont 24:

291-295.

22.

Christensen GJ (1966) Marginal fit of gold inlay castings. J Prosthet Dent 16: 297-305.

23.

Ucar Y, Akova T, Akyil MS, Brantley WA (2009) Internal fit

evaluation of crowns prepared using a new dental crown fabrication technique:

Laser-sintered Co-Cr crowns. J

Prosthet Dent 102: 253-259.

24.

Pradíes G, Zarauz C, Valverde A, Ferreiroa A, Martínez-Rus F

(2015) Clinical evaluation comparing the fit of all-ceramic crowns obtained

from silicone and digital intraoral impressions based on wavefront sampling

technology. J Dent 43: 201-208.

25.

Brawek PK, Wolfart S, Endres L, Kirsten A, Reich S (2013) The

clinical accuracy of single crowns exclusively fabricated by digital workflow—the

comparison of two systems. Clin Oral

Investig 17: 2119-2125.

26.

Anadioti E, Aquilino SA,

Gratton DG, Holloway JA, Denry I, et

al. (2014) 3D and 2D Marginal Fit of Pressed and CAD/CAM Lithium

Disilicate Crowns Made from Digital and Conventional Impressions. J Prosthodont 23: 610-617.

27.

Tsirogiannis P, Reissmann DR, Heydecke G (2016) Evaluation of

the marginal fit of single-unit, complete-coverage ceramic restorations

fabricated after digital and conventional impressions: A systematic review and

meta-analysis. J Prosthet Dent 116:

328-335.

28.

Renne W, Wolf B, Kessler R, McPherson K, Mennito AS (2015) Evaluation

of the Marginal Fit of CAD/CAM Crowns Fabricated Using Two Different Chairside

CAD/CAM Systems on Preparations of Varying Quality. J Esthet Restor Dent 27: 194-202.

29.

Satterthwaite JD, Grey NJA (2008) Peer-group assessment of

pre-clinical operative skills in restorative dentistry and comparison with

experienced assessors. Eur J Dent Educ

12: 99-102.

30.

Goepferd SJ, Kerber PE (1980) A comparison of two methods for

evaluating primary class II cavity preparations. J Dent Educ 44: 537-542.

31.

Jenkins SM, Dummer PM, Gilmour AS, Edmunds DH, Hicks R, et

al. (1998) Evaluating undergraduate preclinical operative skill; use of a glance

and grade marking system. J Dent

26: 679-684.

32.

Tidehag P, Ottosson K, Sjögren G (2014) Accuracy of Ceramic

Restorations Made Using an In-office Optical Scanning Technique: An \textlessi\textgreaterIn

Vitro\textless/i\textgreater Study. Oper

Dent 39: 308-316.

33.

Bindl A, Mormann WH (2005) Marginal and internal fit of

all-ceramic CAD/CAM crown-copings on chamfer preparations. J Oral Rehabil 32: 441-447.

34.

Oyagüe RC, Sánchez-Jorge MI, Turrión AS (2010) Evaluation of

fit of zirconia posterior bridge structures constructed with different scanning

methods and preparation angles. Odontol

98: 170-172.

35.

Nakamura T, et al.

(2005) In vitro study on marginal and internal fit of CAD/CAM all-ceramic

crowns. Dent Mater J 24:

456-459.

36.

Moldovan O, Luthardt RG, Corcodel N, Rudolph H (2011) Three-dimensional

fit of CAD/CAM-made zirconia copings. Dent Mater 27: 1273-1278.

37.

Nawafleh NA, Mack F, Evans J, Mackay J, Hatamleh MM (2013) Accuracy

and Reliability of Methods to Measure Marginal Adaptation of Crowns and FDPs: A

Literature Review. J Prosthodont

22: 419-428.

38.

Kuhn K, Ostertag S, Ostertag M, Walter MH, Luthardt RG, et

al. (2015) Comparison of an analog and digital quantitative and qualitative

analysis for the fit of dental copings. Comput

Biol Med 57: 32-41.

39.

Boitelle P, Tapie L, Mawussi B, Fromentin O (2016) 3D fitting

accuracy evaluation of CAD/CAM copings - comparison with spacer design settings.

Int

J Comput Dent 19: 27-43.

QUICK LINKS

- SUBMIT MANUSCRIPT

- RECOMMEND THE JOURNAL

-

SUBSCRIBE FOR ALERTS

RELATED JOURNALS

- Journal of Carcinogenesis and Mutagenesis Research (ISSN: 2643-0541)

- Journal of Nursing and Occupational Health (ISSN: 2640-0845)

- International Journal of Internal Medicine and Geriatrics (ISSN: 2689-7687)

- International Journal of Radiography Imaging & Radiation Therapy (ISSN:2642-0392)

- Journal of Psychiatry and Psychology Research (ISSN:2640-6136)

- Journal of Cancer Science and Treatment (ISSN:2641-7472)

- Journal of Ageing and Restorative Medicine (ISSN:2637-7403)